With nearly 100 years' experience in Gasket Manufacture and through using the latest CAD/CAM technology, we provide a competitive and responsive service in a range of materials, including Compressed Non-Asbestos Fibre (CNAF), together with Commercial Rubber, Neoprene, Nitrile, EPDM, Butyl, Silicone, Viton® and Polyurethane elastomeric sheet. In addition, we maintain large stocks of various grades and thicknesses of plain and rubber-bonded cork, gasket paper, felt, plain and reinforced graphite, vulcanized fibre, plastic and sponge materials and virgin, filled and/or expanded PTFE. As might be expected of a company with our experience, we recognise and can certify to most British and many other foreign standards.

Whilst with Ashton Seals you will also be able to enjoy the benefits of our existing drawing & template database as well as the skills of our in-house draughtsmen.

GASKETS & JOINTS

Tooling is available to produce all standard pipe flange gaskets (BST, ASA, DIN etc.) from any material.

Simply advise us of:

- Grades required

- Thickness

- Flange specification (e.g. BS 10, ASA 300, BS 4504)

- The nominal bore

- Whether inside bolt circle (ring joint) or full face

For individual requirements to customer specification, new tooling can be produced and gaskets cut in many instances on a 24-hour basis.

Should press cutting not be practical or economical we have the ability and experience to produce hand-made joints to any shape or size. A complete gasket cutting service is available from Ashton Seals in a large range of materials.

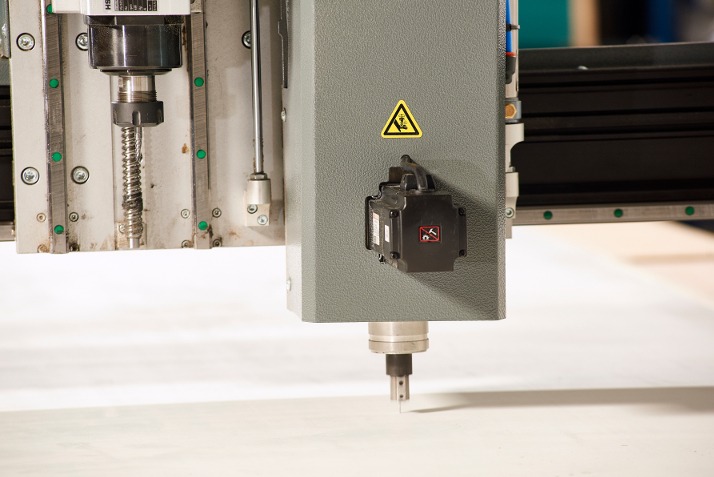

CAD/CAM

Ashton Seals have the capability to manufacture gaskets making use of fast, accurate, automated cutting with the latest CAD/CAM technology. We have the capability to work to samples, drawings or CAD files (DWG files, DXF files etc).

SOFT & SEMI-RIGID MATERIAL CONVERSIONS

At Ashton Seals we consider ourselves to be specialists in Soft & Semi-Rigid Material Conversions rather than purely a Gasket manufacturer. For further information on Soft & Semi-Rigid Material Conversions please click here.

Viton® is a registered trademark of DuPont Dow

Elastomers. If you require genuine DuPont Viton® please specify this to our

sales team.