Parker Chomerics’ Cho-form

(Conductive) and ParPHorm (non-conductive) are two types of form-in-place

gasketing materials that are used in a variety of industries, including

electronics, automotive, and aerospace. These materials are able to conform to

complex shapes and create a watertight seal, making them ideal for applications

where traditional gaskets cannot be used.

Design Considerations

Typically we recommend a minimum gasket height of

0.8mm or 1mm with a maximum of roughly 1.6mm for a singular bead. Higher would

be possible with bead on bead.

To achieve a good quality gasket, we recommend

about 0.2-0.3mm space within the metal chassis, to allow for the bead to sit

nicely within the groove.

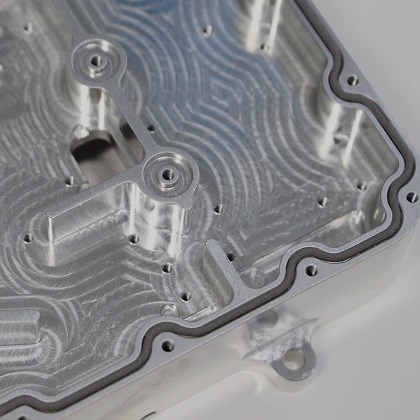

It is preferred for the metal work receiving the

gasket has a U-shaped groove as it may offer more longevity of the gasket bead.

While we can dispense/ facilitate a FIP Gasket on no groove metal work/ etched

metals we cannot assure the same level of longevity.

Benefits of Form In Place

Custom Design - The programmable machine allows for the production of gaskets in various shapes.

Watertight Seal - Cho-form and ParPHorm create a watertight seal that prevents leaks.

Conformable - Cho-form and ParPHorm can conform to complex shapes, making them ideal for applications where traditional gaskets may not suffice.

Durable - Cho-form and ParPHorm are durable materials that can withstand harsh environments.

For more information or to discuss your requirements please contact our Sales Department on 01226 273700 or ask@ashton-group.co.uk